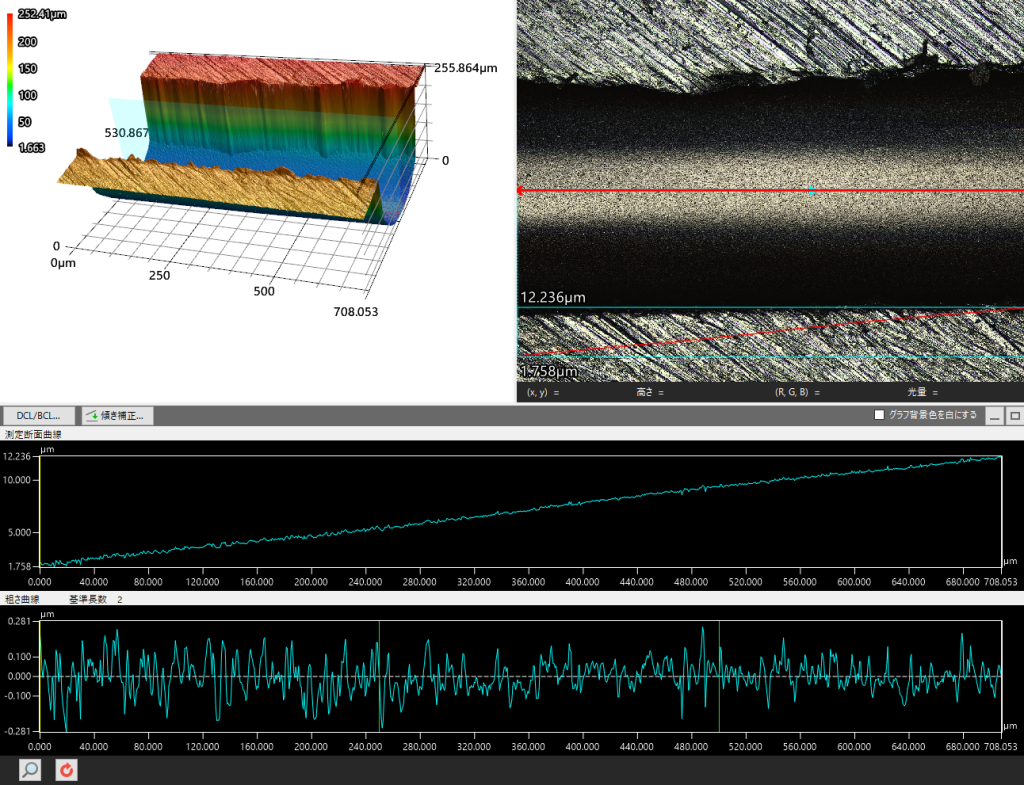

KEYENCE Measurement Report

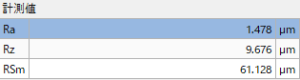

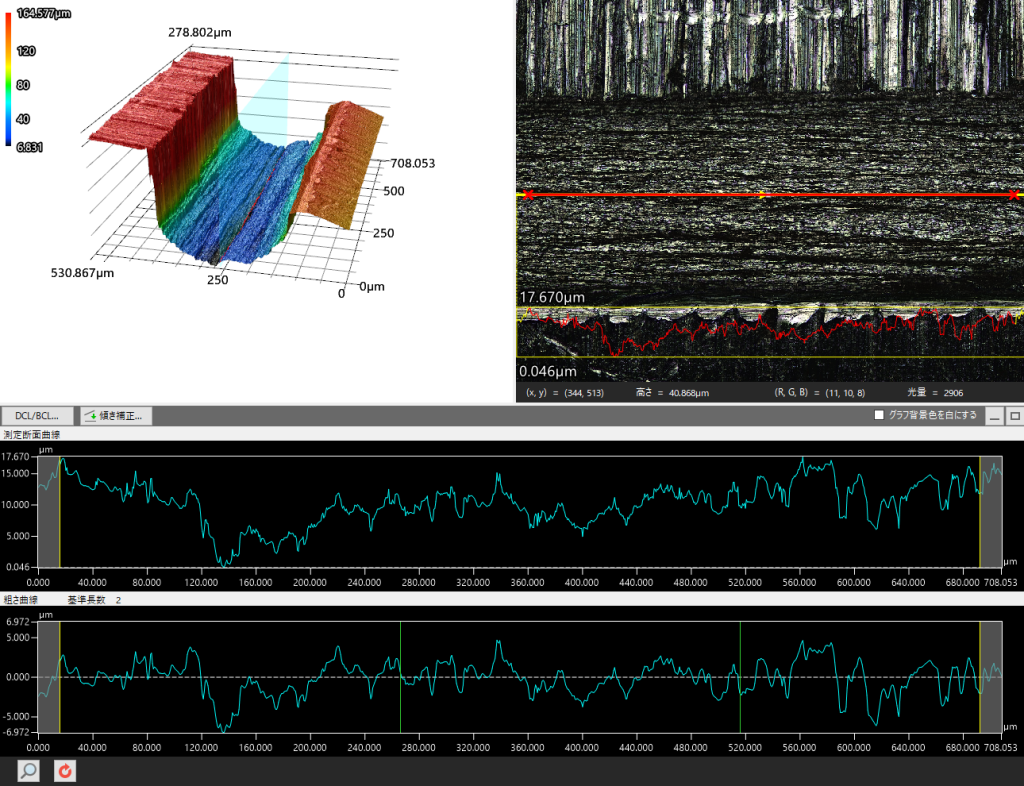

Internal surface roughness evaluation data before and after intelligent fluid polishing

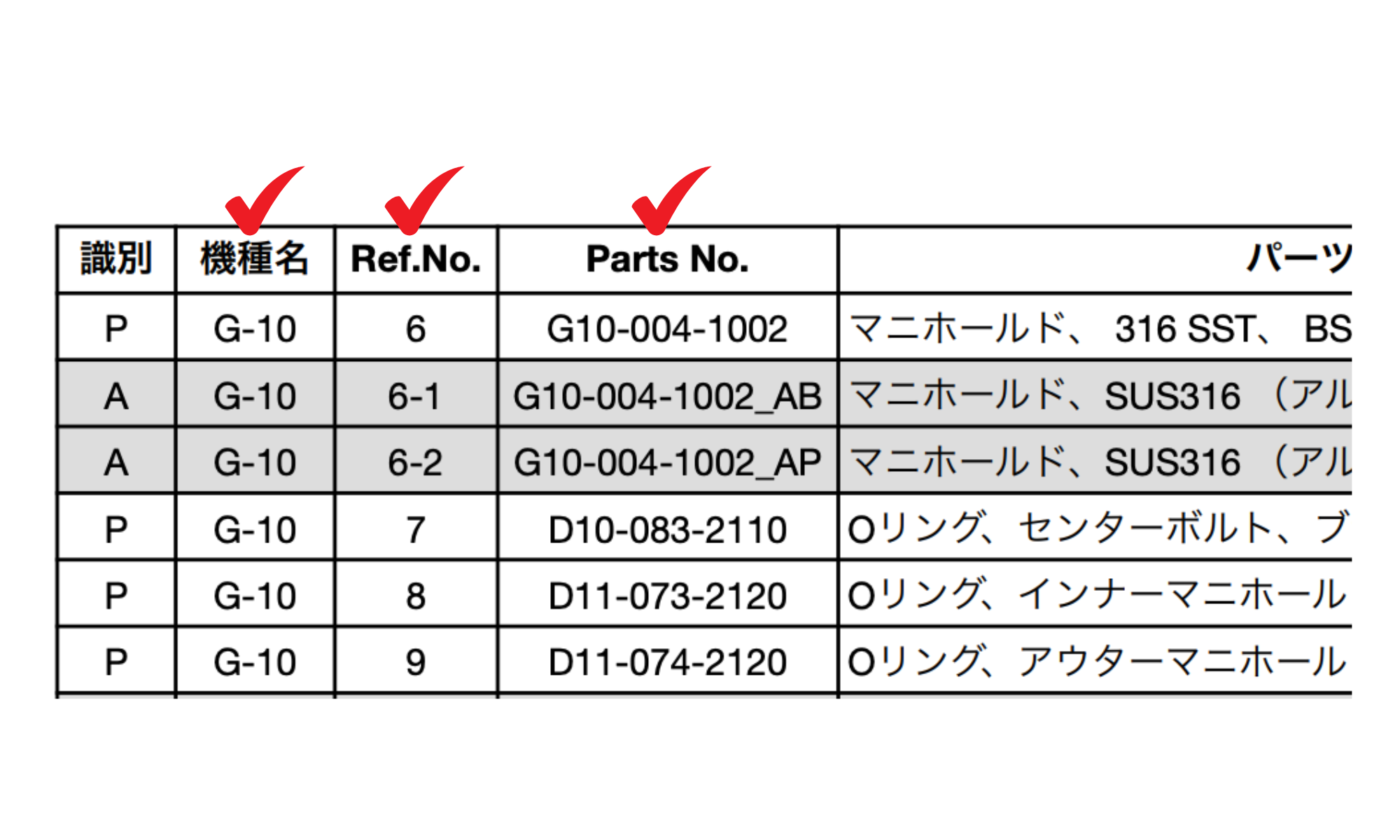

●Material

- SUS304 Stainless pipe (Φ0.3 pipe)

●Measuring machine : KEYENCE VK-X3000

●Method: laser

●Resolution : 0.01 nm

1-Before. SUS304 Stainless pipe Raw material (before polishing)

1-After. SUS304 Stainless pipe After fluid polishing

《Comparison of measured value》

Ra:1.478μm → Ra:0.070μm

Rz:9.676μm → Rz:0.519μm

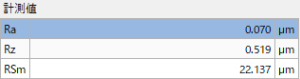

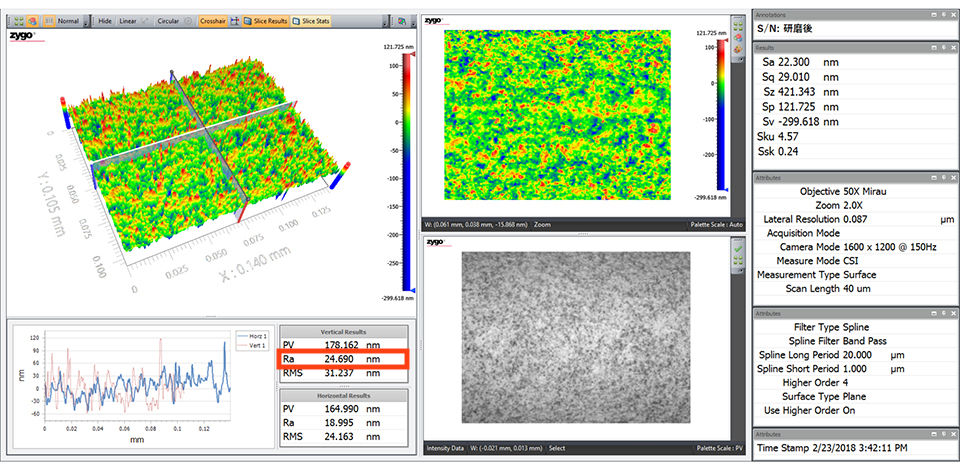

ZYGO Newview9000 Measurement Report

Internal surface roughness evaluation data before and after intelligent fluid polishing

●Material

1. SUS316L Stainless pipe (semi-seamless pipe)

●Measuring machine : ZYGO Newview9000

●Method : White interferometer

●Measurement time : 5 sec.

●Resolution : 0.1 nm

1-Before. SUS316L Stainless pipe Raw material (before polishing)

《Roughness evaluation》

Ra:24.690nm = 0.024μm(Micrometer transformation)

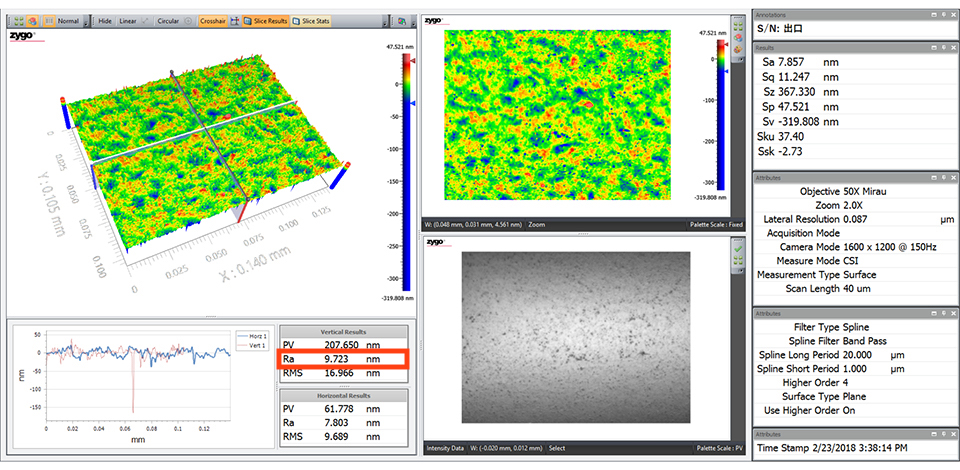

1-After. SUS316L Stainless pipe After fluid polishing

《Roughness evaluation》

Ra:9.723nm = 0.009μm(Micrometer transformation)

We offer free consultation for testing and equipment purchase.

We can help you solve your problems!